CxAlloy Blog

News and updates for CxAlloy TQ and CxAlloy FM

Featured Post

Most Recent Post

Optimizing Success: Best Practices in Commissioning Project Management

Commissioning is a critical aspect of construction projects, ensuring that systems and components are designed, installed, and tested to meet the Owner’s Project Requirements (OPR). Effective project management during commissioning is essential for achieving optimal...

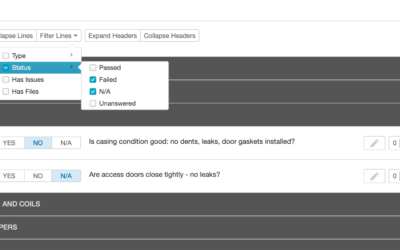

Line Types Feature Updates

If you've used our commissioning software for managing checklists and tests, you know how important it is to capture and track various types of data as part of your workflows. From providing instructional text on lines to collecting files, our platform provides many...

iOS Update: Version 7.1 Out Now

The year might be coming to a close, but we’re still hard at work on CxAlloy TQ updates. We’re excited to fill you in on the new features that were released with our iOS update. Version 7.1 is here - so what does this mean for you? This update includes multiple new...

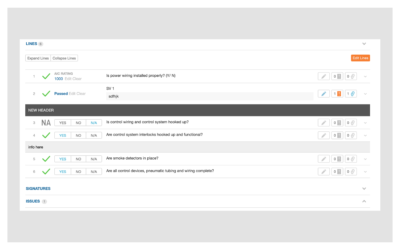

Enhancements to Line Types

In mid-October 2022, we released significant updates to checklist and test lines, an update we’re calling Line Types. These updates affect how users answer and edit lines and introduce new capabilities. Additional customization of these lines has been an important and...

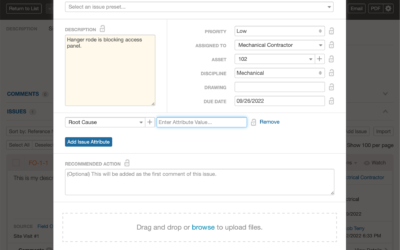

New Features – Issue Attributes and Issue Presets

We've just launched two new features in for building commissioning: Issue Attributes and Issue Presets. These represent a significant enhancement to CxAlloy commissioning tools that expands what you can do with CxAlloy issues. What does this mean for commissioning...

Dropping iOS 14 Support in the CxAlloy iOS App

The CxAlloy iOS app will drop support for iOS 14 starting with version 6.8 of the iOS app. If you are running iOS 14, version 6.8 of the app and future app updates will not be available until you update your device to iOS 15. This does not prevent you from using...

CxAlloy TQ Downtime Postmortem

On Wednesday, March 23, CxAlloy TQ experienced a period of extended downtime as the result of a failed database migration. This postmortem will explain what went wrong, the steps we took to recover, and the changes we are making to mitigate the chances of such an...

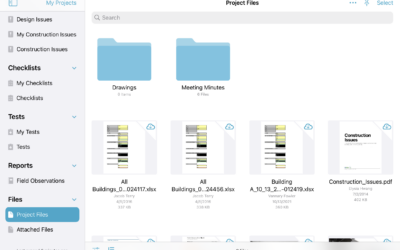

Project Files Now in the iOS App with Offline Support

Since the first version of the iOS app you’ve been able to add and view files attached to issues, checklists, and other items in the app. Now, with version 6, for the first time the Project Files section comes to your Apple device. With this addition you can view,...

Sunsetting Checklists with Sections

Three years ago, we began offering an upgraded project experience that enables additional functionality and adds new features to CxAlloy. Many of these exciting features are only available to updated projects. Starting on November 30, 2021 we will begin automatically...

A Faster, Prettier, and Smarter Account Projects List

We recently released an update to the Account Projects List that makes it faster, prettier, and a little smarter. Faster One of the best parts of the account projects list is the ability to see each project's dashboard right in the list. While this feature is pretty...

Optimizing Success: Best Practices in Commissioning Project Management

Commissioning is a critical aspect of construction projects, ensuring that systems and components are designed, installed, and tested to meet the Owner’s Project Requirements (OPR). Effective project management during commissioning is essential for achieving optimal...

Line Types Feature Updates

If you've used our commissioning software for managing checklists and tests, you know how important it is to capture and track various types of data as part of your workflows. From providing instructional text on lines to collecting files, our platform provides many...

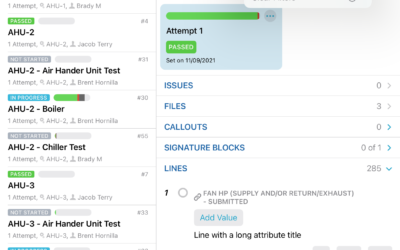

iOS Update: Version 7.1 Out Now

The year might be coming to a close, but we’re still hard at work on CxAlloy TQ updates. We’re excited to fill you in on the new features that were released with our iOS update. Version 7.1 is here - so what does this mean for you? This update includes multiple new...

Enhancements to Line Types

In mid-October 2022, we released significant updates to checklist and test lines, an update we’re calling Line Types. These updates affect how users answer and edit lines and introduce new capabilities. Additional customization of these lines has been an important and...

New Features – Issue Attributes and Issue Presets

We've just launched two new features in for building commissioning: Issue Attributes and Issue Presets. These represent a significant enhancement to CxAlloy commissioning tools that expands what you can do with CxAlloy issues. What does this mean for commissioning...

Dropping iOS 14 Support in the CxAlloy iOS App

The CxAlloy iOS app will drop support for iOS 14 starting with version 6.8 of the iOS app. If you are running iOS 14, version 6.8 of the app and future app updates will not be available until you update your device to iOS 15. This does not prevent you from using...

CxAlloy TQ Downtime Postmortem

On Wednesday, March 23, CxAlloy TQ experienced a period of extended downtime as the result of a failed database migration. This postmortem will explain what went wrong, the steps we took to recover, and the changes we are making to mitigate the chances of such an...

Project Files Now in the iOS App with Offline Support

Since the first version of the iOS app you’ve been able to add and view files attached to issues, checklists, and other items in the app. Now, with version 6, for the first time the Project Files section comes to your Apple device. With this addition you can view,...

Sunsetting Checklists with Sections

Three years ago, we began offering an upgraded project experience that enables additional functionality and adds new features to CxAlloy. Many of these exciting features are only available to updated projects. Starting on November 30, 2021 we will begin automatically...

A Faster, Prettier, and Smarter Account Projects List

We recently released an update to the Account Projects List that makes it faster, prettier, and a little smarter. Faster One of the best parts of the account projects list is the ability to see each project's dashboard right in the list. While this feature is pretty...